Innovative technology, breaking through energy limits

UltraXel provides excellent performance for wide-temperature lithium batteries, stable operation from -40°C to 85°C, high-rate discharge, military-grade reliability, and energy solutions for various fields.

Global Reach

Patents

Lithium Expertise

Certifications

Innovation

Our Mission Powering the Future with High-Performance Lithium Battery Solutions

Leading Innovation in Lithium Battery Technology

With over 20 years of experience in lithium battery R&D and manufacturing, our products deliver exceptional performance across wide temperature ranges, support high-rate discharge, and ensure long-term stability. Our wide temperature lithium cells are trusted in critical sectors like automotive electronics, telecommunication equipment, and industrial power systems, delivering reliable power even in the harshest environments.

Strict Testing Ensures Superior Battery Quality

We apply comprehensive testing protocols to every lithium battery cell, using state-of-the-art equipment to validate safety, durability, and consistency. From thermal stress testing to vibration simulation and particle analysis, our precision testing guarantees high-performance lithium batteries built for extreme environments and mission-critical applications.

Expert Team Behind Reliable Lithium Battery Solutions

Our team includes over 100 specialists in electrochemistry, materials engineering, and power system design. Their technical expertise fuels continuous innovation, allowing us to provide next-generation industrial lithium battery solutions that exceed global performance and safety standards.

UltraXel Battery Core Technologies

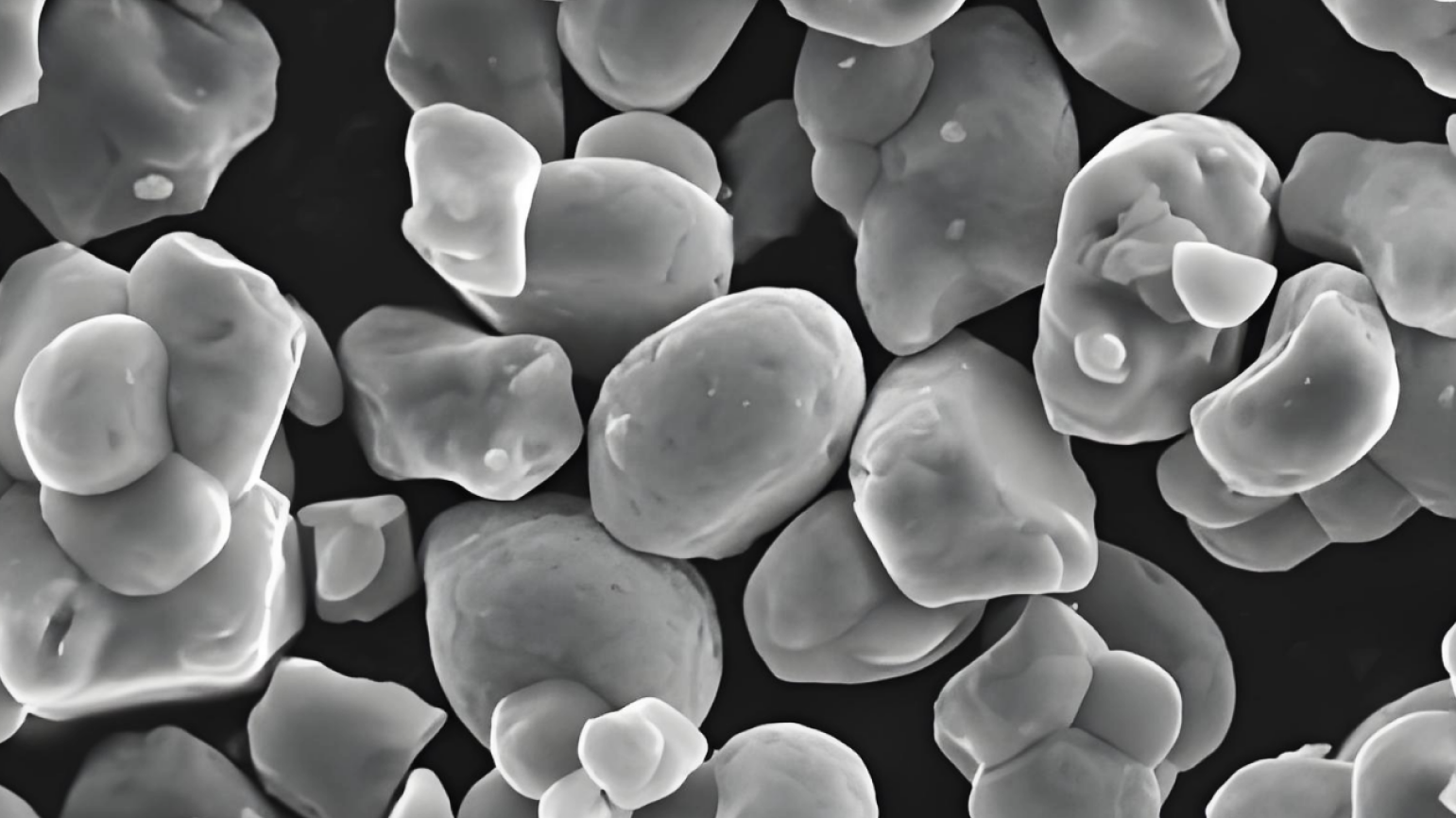

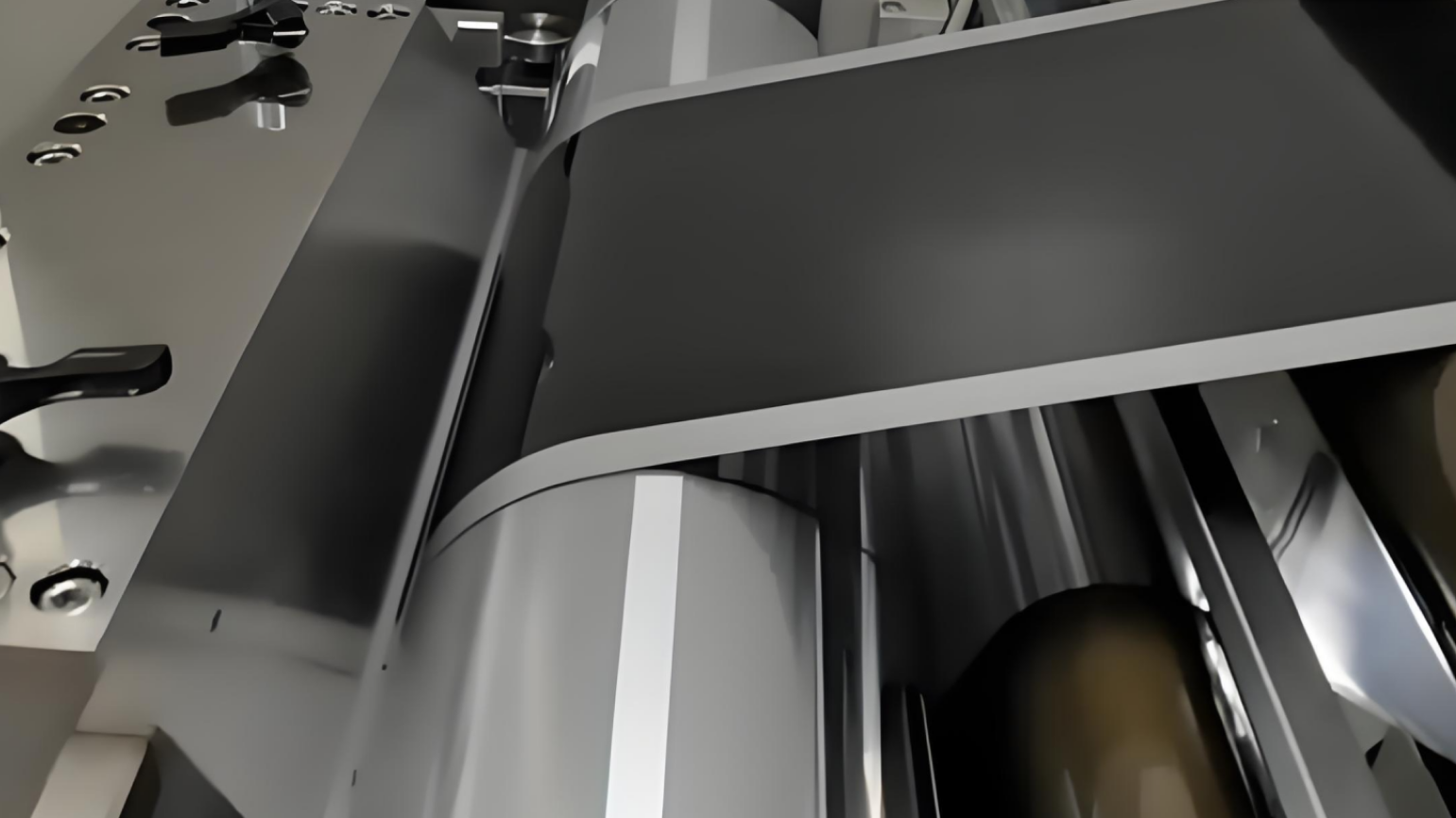

Cathode Material Optimization

• Nanomaterial treatments and composites with other materials improve low-temperature performance.

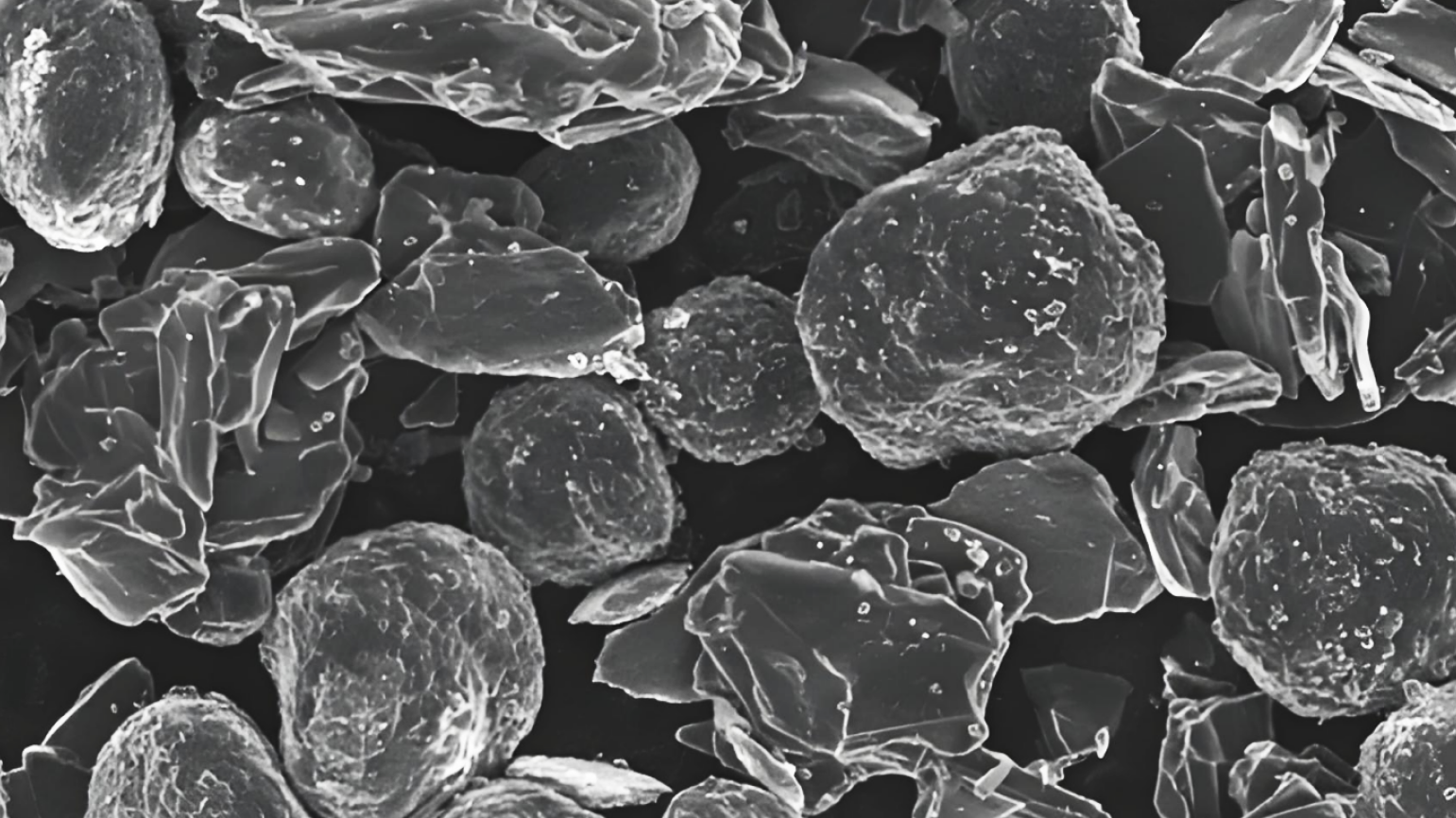

Anode Material Modification

• Special surface-treated graphite enhances the stability of the anode reaction at high temperatures.

High-Temperature Electrolyte Formula

• High-boiling point solvents and stable lithium salts reduce electrolyte vaporization and decomposition at high temperatures.

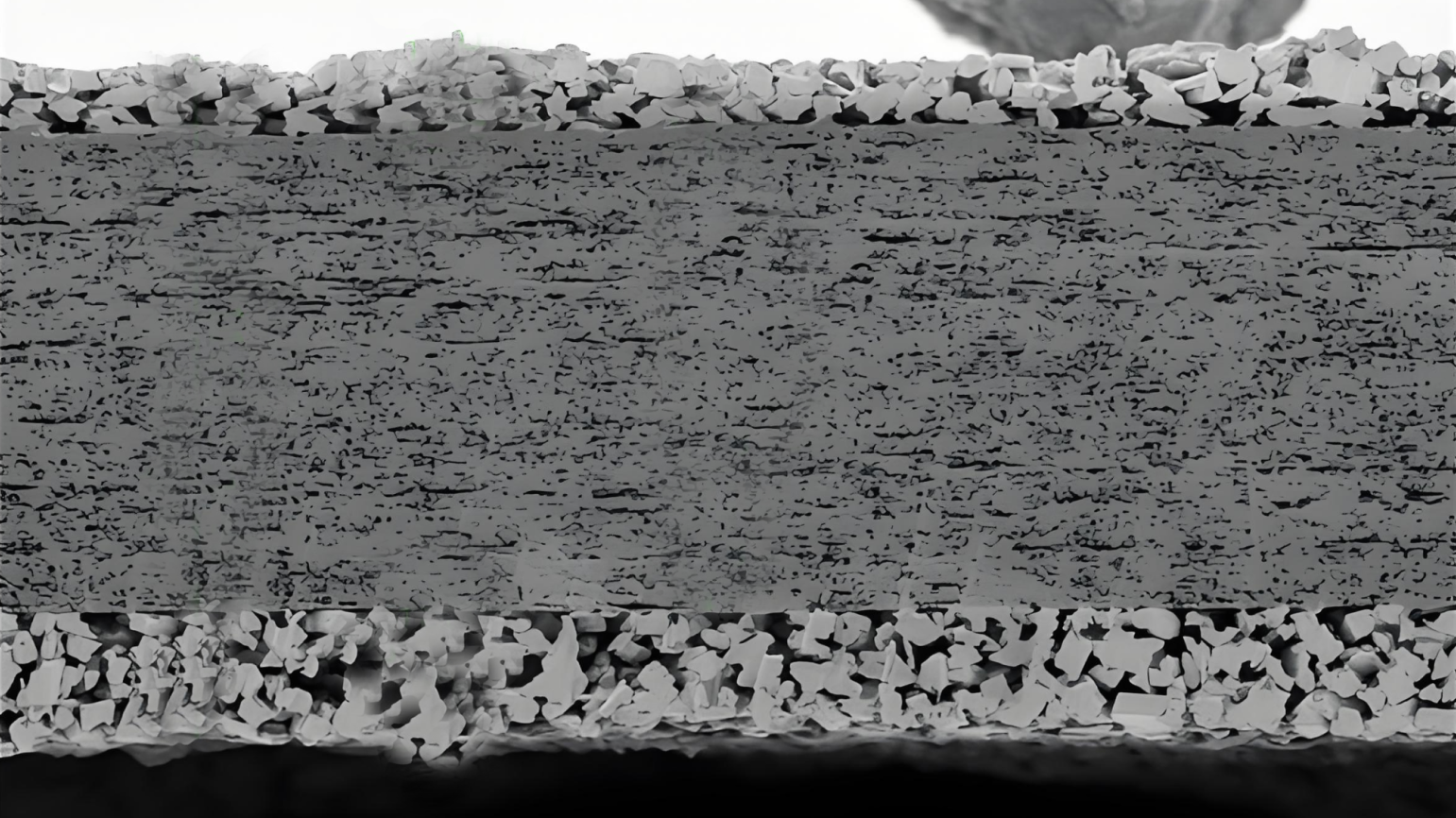

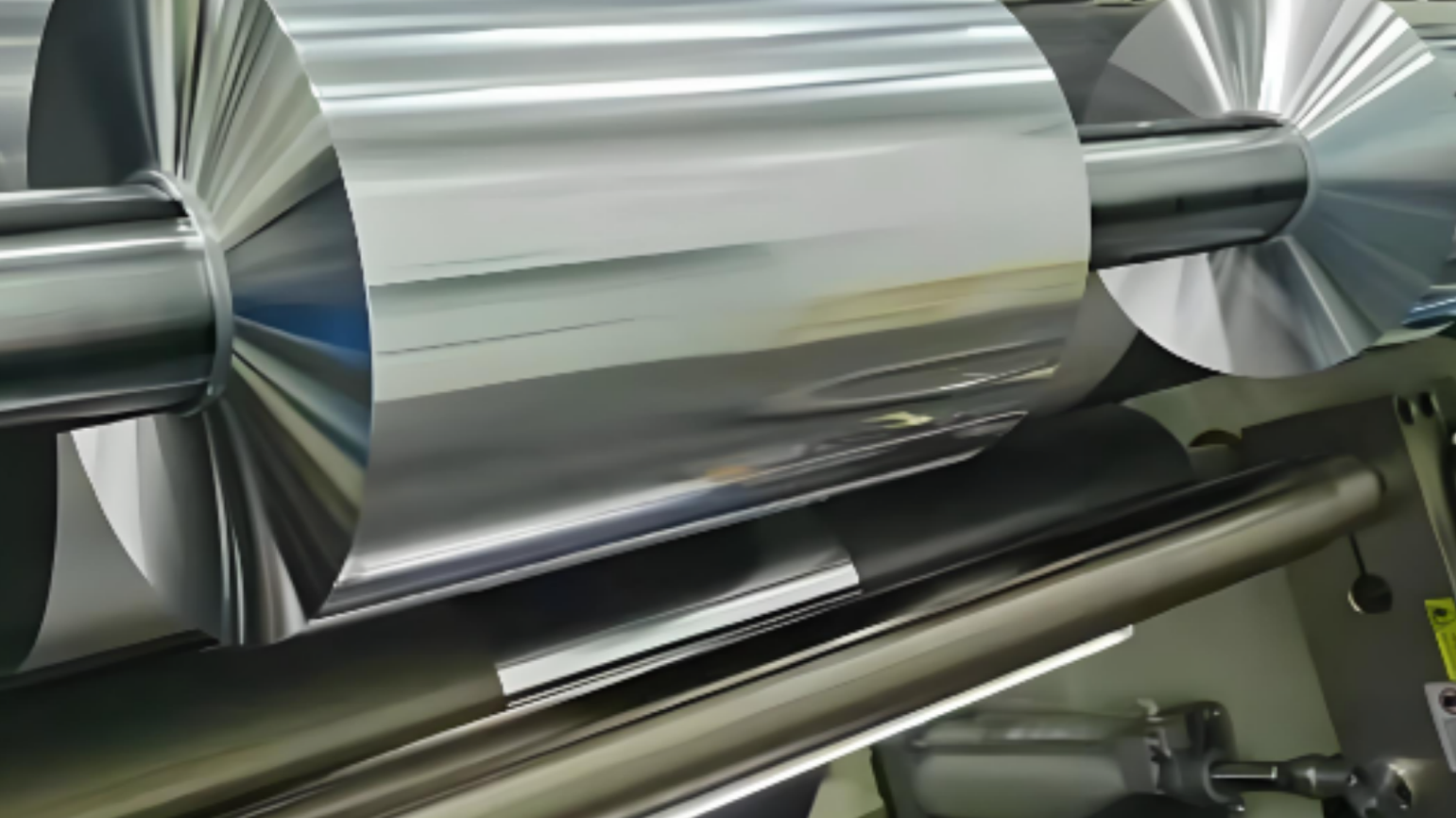

Membrane Coating Technology

Binder Technology

Cathode Material Optimization

• Surface coating and doping modifications improve the thermal stability of the material.

Anode Surface Structure Optimization

• Artificial or natural graphite, treated with surface modification and nanomaterial techniques, enhances lithium-ion insertion and extraction performance at low temperatures.

Electrolyte

• Using low-viscosity solvents and high-conductivity lithium salts reduces impedance at low temperatures. Low-temperature film-forming additives reduce SEI layer impedance on the electrode surface, improving performance in low-temperature charging and discharging.

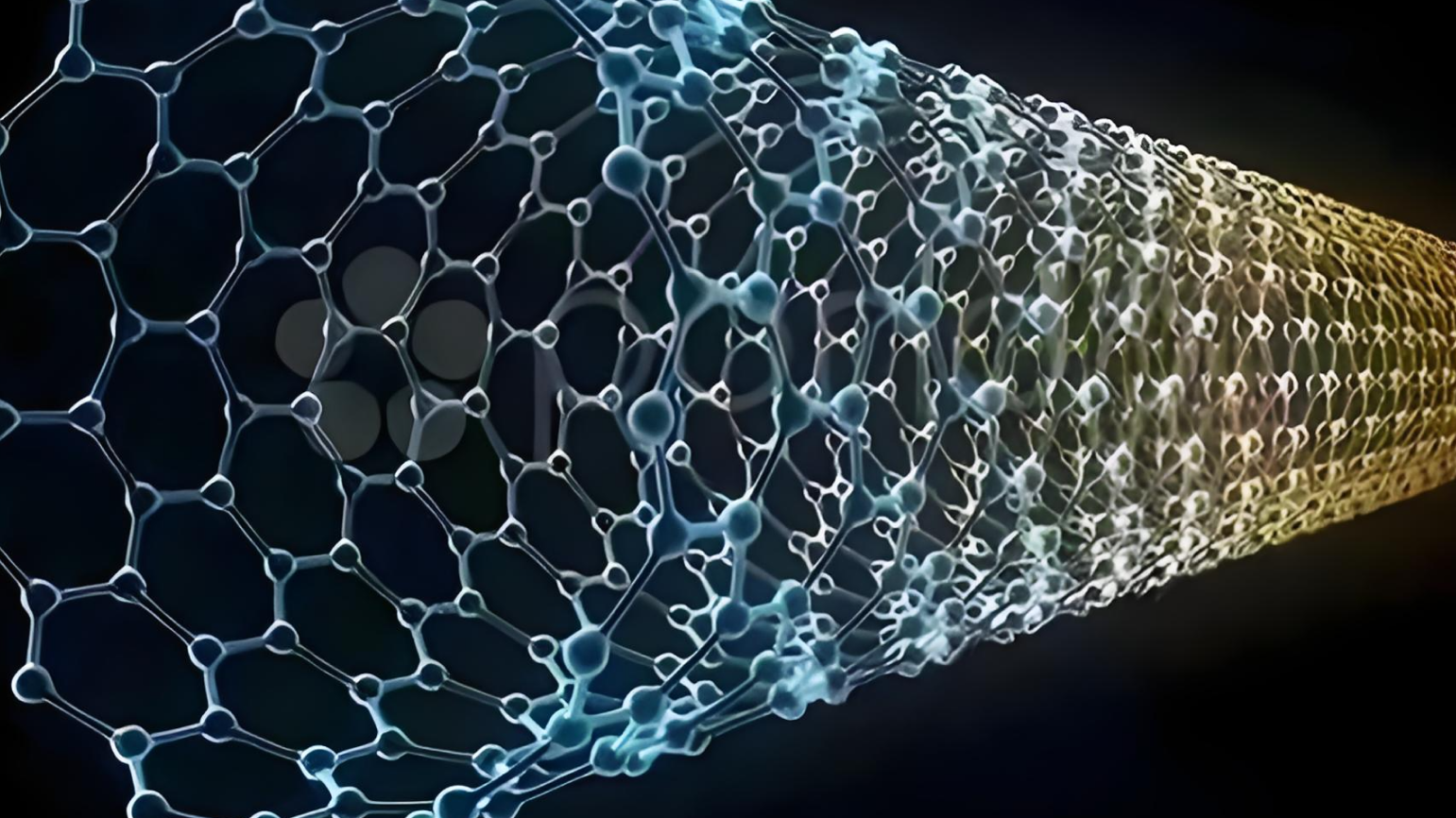

Conductive Additive Upgrade

• Carbon nanotubes and graphene are used as conductive agents to reduce internal resistance and improve conductivity at low temperatures.

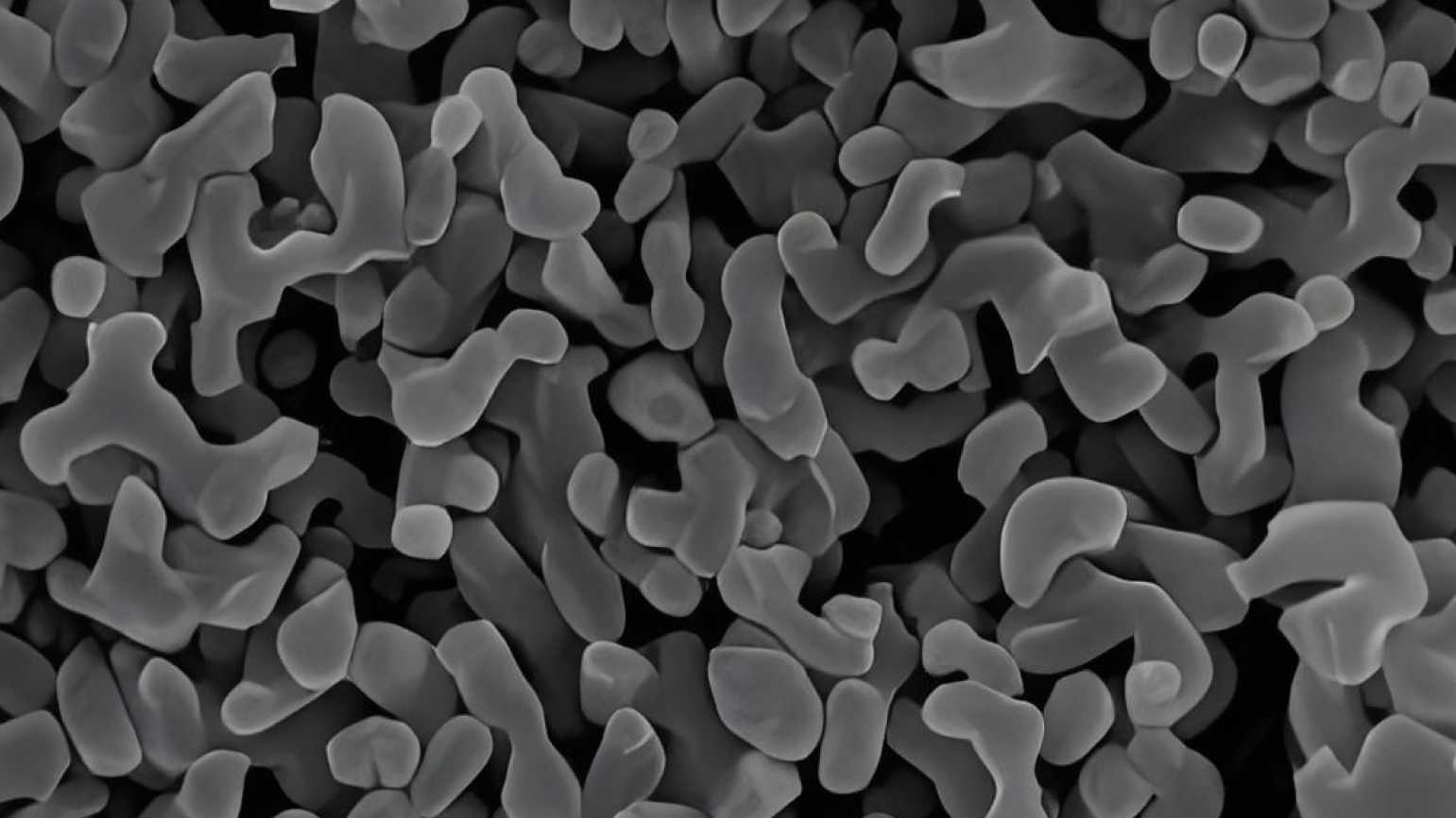

Separator Materials

• High-porosity separators enhance electrolyte permeability, aiding ion transport in low temperatures.

Ceramic-Coated Separator

• Ceramic coatings prevent separator shrinkage at high temperatures, avoiding short circuits.

Explosion-Proof Valve Design

• CID (Current Interrupt Device) quickly disconnects overload currents.

Membrane Micropore Control

• High-precision microporous separators close the pores to cut off ion channels when the temperature rises.

Flame Retardant Electrolyte

• Incorporating flame retardants reduces the risk of combustion during thermal runaway.

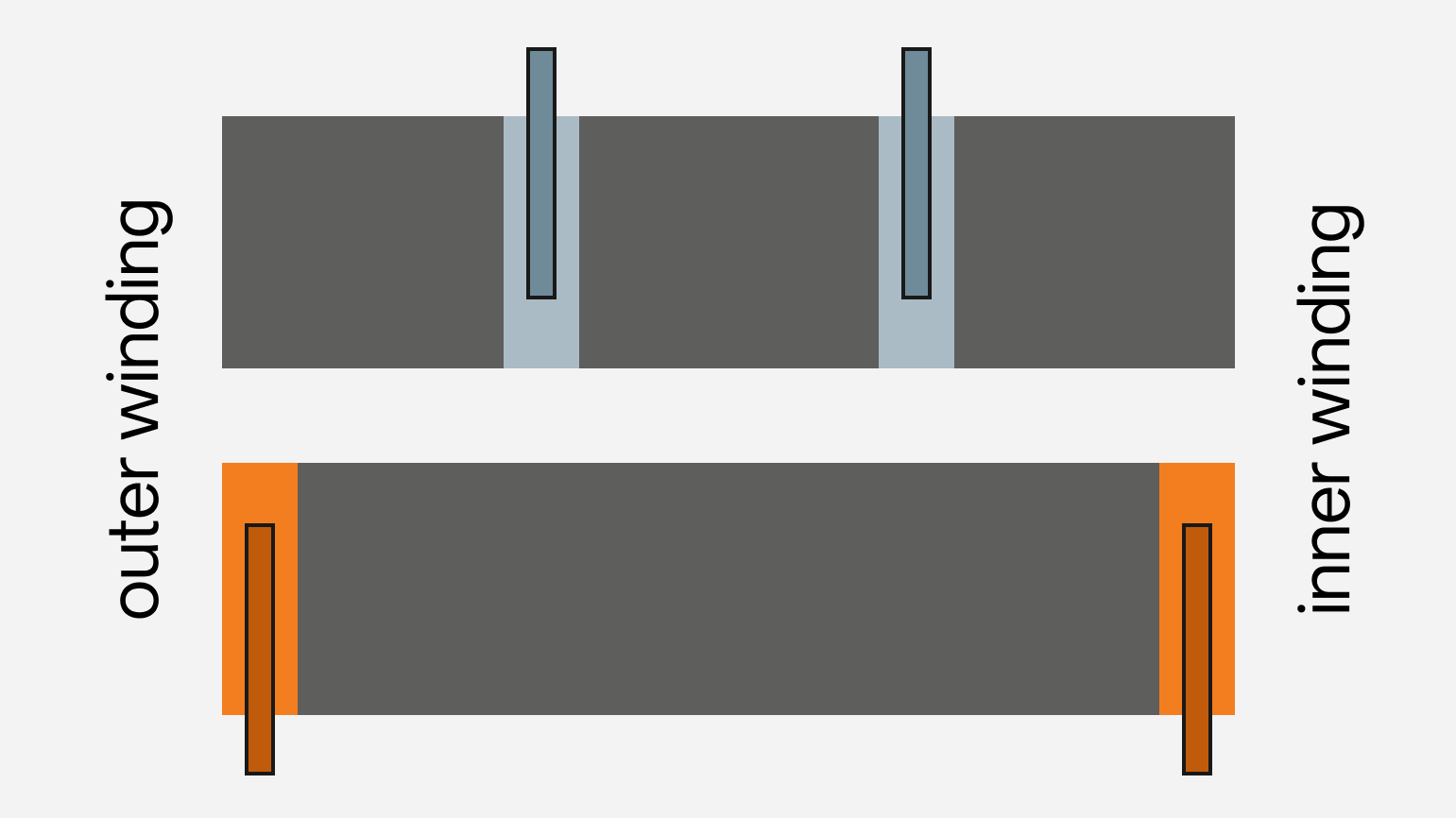

Multi-Tab Design

• Using multiple or full tabs for uniform current distribution, reducing internal resistance.

Electrode Plate Design Optimization

• Optimizing electrode plate area density and compaction density to lower internal resistance.

Conductive Additive Enhancement

• Using high-conductivity carbon nanotube and graphene composite additives to improve high-rate performance.

Current Collector Pre-Coating

• Pre-coating current collectors with conductive carbon to reduce internal resistance.