As the automotive industry undergoes comprehensive electrification and intelligent transformation, a long-overlooked technical bottleneck is gradually coming to light—the critical impact of temperature on electronic systems. The performance limitations of traditional lithium batteries in extreme temperature environments have become a key factor constraining the development of automotive electronics. The emergence of wide-temperature lithium batteries is now bringing revolutionary changes to this industry.

During the winter of 2022-2023, Oslo, Norway, experienced extreme cold with temperatures plunging to -22°F(-30°C) , leading to widespread reports from local electric vehicle users of significantly reduced driving ranges.Extreme heat poses equally severe challenges. Engine compartment temperatures can soar above 185°F(85°C), severely testing electronic components. Conventional lithium batteries suffer electrolyte decomposition and electrode material degradation under high temperatures, leading not only to performance degradation but also thermal runaway risks. A U.S. National Highway Traffic Safety Administration report indicates that in hot regions, vehicle electronics failure rates exceed those in temperate zones by 37%.

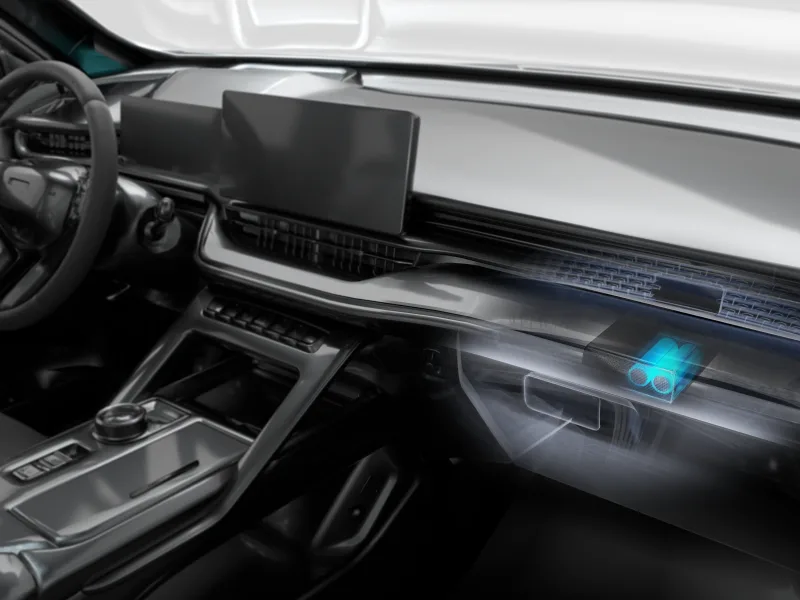

To address these challenges, wide-temperature lithium batteries have achieved breakthroughs through three major technological innovations. First is the revolution in material systems. Researchers have developed novel electrolytes containing special additives that maintain excellent fluidity even at -40°F(-40°C). Simultaneously, electrode materials treated with surface modification technology significantly enhance lithium-ion insertion and extraction efficiency under extreme temperatures. Second is the application of intelligent thermal management systems. An advanced Battery Management System (BMS) monitors temperature changes in real time, automatically activating heating functions in cold conditions and cooling systems in hot conditions to ensure the battery consistently operates within its optimal temperature range. Third is structural design optimization. By refining the internal battery structure, thermal resistance is reduced and heat transfer efficiency is enhanced, resulting in more uniform temperature distribution.

These technological innovations deliver remarkable practical outcomes. In extreme cold testing, automotive electronics equipped with wide-temperature lithium batteries function normally at-40°F( -40°C). The startup time for in-vehicle infotainment systems is only 15% longer than at ambient temperatures—significantly outperforming traditional battery systems that often require several minutes of waiting. During high-temperature testing, even when ambient temperatures reach 185°F(85°C), the temperature difference within the battery pack remains controlled within 41°F( 5°C), substantially reducing the risk of thermal runaway.

In this era of challenges and opportunities, wide-temperature lithium batteries embody the automotive electronics industry’s spirit of pushing boundaries and pursuing excellence. As the technology matures and becomes more widespread, we have every reason to believe that temperature will no longer be a barrier to automotive electronics development—instead, it will become a driving force for technological innovation. This battle against temperature extremes is now writing a new chapter in the automotive industry.

UltraXel Wide-Temperature Lithium-Ion Batteries leverage advanced electrolyte formulations, optimized electrode materials, and intelligent BMS technology to deliver stable performance across a wide operating range from-40°F to 85°F(-40℃ to 85℃). Featuring high energy density, long cycle life, and comprehensive safety protections, they have been certified by international safety standards and support customized solutions. Whether for automotive electronics, or demanding industrial applications in extreme environments, UltraXel wide-temperature lithium-ion batteries provide customers with efficient, reliable, and safe energy solutions.